Energy

LILLNORD is keeping a close eye on energy consumption and has therefor developed the following to ensure as little energy needed as possible

- Insulated floor with automatic / adjustable heating

- Insulated steam container

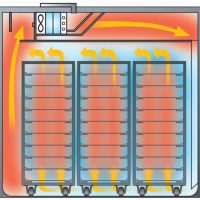

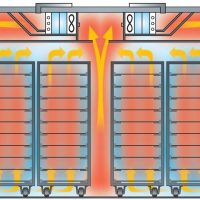

- 200 step intelligent fan speed regulation

- Computer control ensuring longest possible intermissions and shortest possible running time

- PID temperature and humidity control

- Low energy triple glass windows

- 80 or 120 mm insulation

- Specially developed defrosting curves to ensure a natural defrosting

Accessories

Individually adapted options

LILLNORD has developed a wide range of options and accessories in liaison with its customers

- FlexBaker, proved products, ready for baking off in 6-8 hours

- UV light

- Hatches for trays

- Manual or automatic sliding door

- Air curtain for all types of door openings

- Pipe bumper rails in stainless steel or PVC

- Inspection panel, giving access to ovens, being serviced from the side

- and the list goes on

Room sizes

LILLNORD provides its own panel production, ensuring the best possible utilisation of the space in the bakery.

A standard panel size of 150mm width on our panels (80 and 120mm thick) provides us with a flexible starting point for the serial production of our units. As a consequence, every single unit can be tailor-made for an optimal utilisation of the available space in the bakery – even for combination units.

Our panels are constructed the sandwich way, increasing its ability to isolate and ensuring as much neutralisation of the surrounding temperature as possible and protecting the temperature inside the unit.

Front and door(s) are in stainless steel, type leinen as a standard on all units. The exact robustness needed in a busy, modern bakery environment.

Dimensions: We offer a tailor-made solution in order to optimally utilise the space in your bakery. For a tailor-made offer, please contact us per phone, mail or through this link “request offer”